Steel constructions and tubes, a perfect match

In the Benelux, many constructions are built in steel. Steel is a winner with regard to sustainability and speed of construction. Tubes and hollow sections are preferred in steel constructions because of their appearance and properties. Architects like tubes because of their esthetic, closed shape. And when buckling load is important for a construction, tubes are more suitable than beams with the same weight.

My name is James Muyldermans, I am 30 years old and was born in Belgium. I have been working at Van Leeuwen for 7 years now, both at Van Leeuwen in Belgium and at Van Leeuwen in Zwijndrecht, Netherlands. I enjoy my work as account manager, which means I am the central contact person for customers active in the steel construction market. In this market I have specialized myself in coordinating large steel construction projects. I am happy to tell you more about it in this blog!

Steel constructions are everywhere

Our business in steel constructions often mean large projects with long lead times. Such projects have different stages and at each stage, I help the customer to find the most efficient solution.

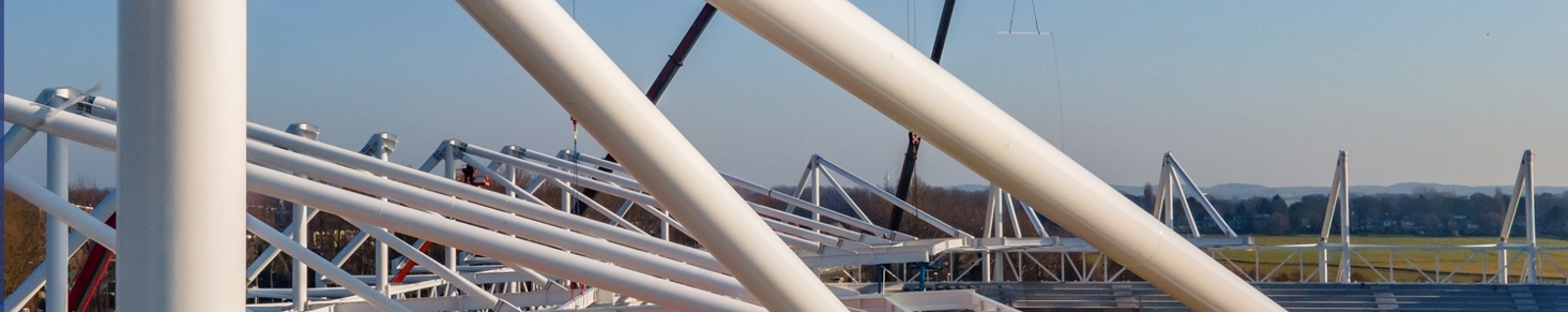

You might wonder what kind of steel constructions we are talking about? In the last few years, for example, a lot of distribution centers, data centers and power stations have been built in our region. These power stations, also called “kV lines” are transformation stations to convert high voltage electricity to low voltage electricity ready for use in companies and households. Other examples of steel constructions are bridges, tunnels, railway stations and motorway gantries that hold traffic or matrix signs.

Project management is mostly coordination

Project management sounds nice, but in our business it is really important. At Van Leeuwen we are used to manage projects and are organized accordingly. In practice, project management means for me that I assure that the tubes are delivered on time, at the right place, in the right quantities, accompanied by the right documents and material certificates.

Obviously I don’t do all of this just by myself. For each project we form a team of colleagues with different specializations that are required. My role is to coordinate everything.

With our network we cross borders

We sell a lot of tubes from our own, vast stock in Zwijndrecht. But we can also deliver the required tubes directly ex-mill, using our worldwide procurement network and our excellent possibilities for temporary storage. On the other hand, our network of stock keeping locations in countries around us helps me as well. If a fast delivery is required and we are temporarily out of stock in Zwijndrecht, I can rely on stocks from our sister companies nearby. Our stock does not stop at the border!

Trends in the steel construction market

An important topic for steel construction companies is the steel grade of the tube and its properties. Over the last (almost) hundred years, Van Leeuwen has built up a lot of knowledge that I can use in advising my customer about this. More and more customers choose higher steel grades than before, like S355J2H. Years ago, Van Leeuwen already decided to stock the higher steel grades only. They are standard for us. When we say Van Leeuwen is a quality supplier, that is not an empty slogan.

Another topic for discussion is the surface of the tube. Because of their esthetical properties, tubes and hollow sections are often used where they remain visible for the public. Just look up to the roof of a railway station or a sports stadium, for example, and often you see tubes. Irregularities in the surface become more visible after the construction is painted. In these cases we advise our customer to use welded instead of seamless tubes. Due to a different production process, welded tubes have a much smoother surface than seamless tubes.

The highest tube of the Benelux is a Van Leeuwen tube!

One of the joys of my work is that I see the results around me every day. I think steel constructions really contribute to a beautiful environment. A recent project literary stands out: our contribution to the new “Zalmhaven” (salmon harbor) tower in Rotterdam. With 215 meter, it is the highest building in the Benelux. On its top, a pole has been mounted. I supplied the welded, hot formed, 12.5 m long steel tube of 914 x 12 mm for the construction of that pole. Moreover, I supplied the hollow sections for the pyramid-shaped top floors of the tower. For us this was not the biggest of projects, but obviously a very special one!

I live in Rotterdam and from my apartment I can see this impressive tower. I cannot not get enough of it and tell my story to everybody, sometimes to the annoyance of my girlfriend. However, if you watch this short video, you will understand what I mean!